Co-packers expend a significant degree of methods on entire-scale bottling. They need to know that your solution is able to scale to the biggest levels.

Aseptic method manufacturing makes it possible for these products being made within a sterile natural environment, permitting them to maintain their usefulness while becoming Secure to inject into sufferers.

Purchasing Liquid bottle filling equipment can have a profound beneficial effect on pharmaceutical businesses, leading to a notable Raise inside their General general performance.

From early-stage enhancement as a result of industrial generation, Renaissance offers the knowledge and regulatory history to help make us the right lover to your sterile injectable and preservative-free of charge nasal spray plans. To learn more please go to

Clipster® is a single-use Remedy for disconnecting tubing at any stage in the process while maintaining sterility.

To begin using the Biowelder® TC automatic tube welder, an operator inserts the tube holders, the disposable blade and also the TPE tubes and initiates the welding method through the touch display screen.

Eisai, Seidenader, and Brevetti automated inspection equipment as much as 300 units/min; lighted inspection booths with black and white backgrounds; Groninger labeler and plunger rod insertion machine

Sources have to be saved and allocated for the most vital dangers, so It will be essential to prioritize pitfalls. Because of chance management, needs are fulfilled, and also the Corporation’s targets are supported by prompt actions and measurements carried out to limit hazard That may be fatal to individuals or result in an item recall.

The Table under lists the main course of action parameters as well as their risk to package deal integrity. All of these parameters have an effect on the packaging course of action.

Modern day aseptic filling devices use RABS (limited access barrier technique) or isolator technological innovation. Both equally RABS and Isolators prohibit outdoors contamination in the filling method and preserve ISO 5/Course A ailments inside the filling and packaging regions. These rooms are more frequently referred to as clean rooms.

From the inventive dip tube tip for maximum fluid removing to the QUICKSEAL® aseptic disconnection, Mycap® is surely an adaptable Answer for virtually any application.

Resolution filter shall be wetted with item Answer, its integrity is examined, and exercise is recorded in BMR.

The written content of our Site is always out there in English and partly in other languages. Opt for your most popular language and We're going check here to tell you about the written content in that language, if obtainable.

Usually, aseptic processing is used when terminal sterilization will not be possible for manufacturing sterile medicines. To this conclude, aseptic processing commences with sterilizing the drug product, together with its read more container and any closures, separately just before assembling these products with each other.

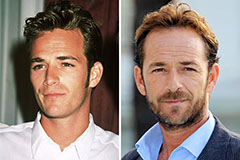

Luke Perry Then & Now!

Luke Perry Then & Now! Scott Baio Then & Now!

Scott Baio Then & Now! Seth Green Then & Now!

Seth Green Then & Now! Melissa Sue Anderson Then & Now!

Melissa Sue Anderson Then & Now! Heather Locklear Then & Now!

Heather Locklear Then & Now!